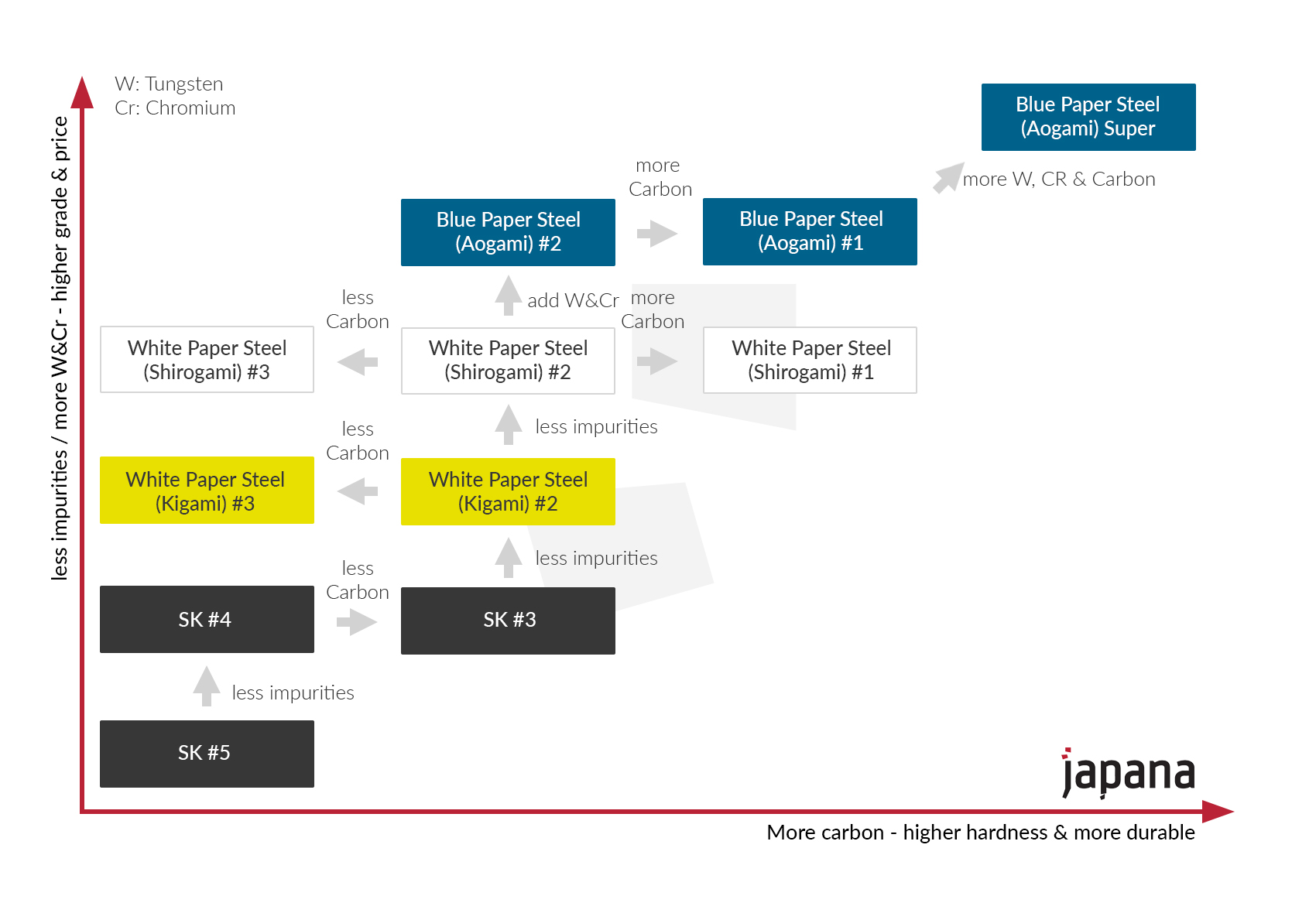

The Queen of the steels – Aogami Blue Super (Hitachi Metals Ltd.) is one of the greatest Japanese Carbon Steels. In addition to containing more Carbon, Chromium and Tungsten than Blue Steel No.1, it also includes Molybdenum. It has a very good edge sharpness and excellent edge retention. It is also capable of attaining high hardness without being brittle. Consequently, many knife enthusiasts rate Aogami Super as one of the very best high carbon steels in the world.

White, Yellow, Blue And Super Blue

The Moritaka range and Shinji have an exceptionally hard Super Blue Steel cutting edge and are laminated in Stainless.

The downsides?

In the quest for the “perfect knife steel” (hint: there is none) there are always compromises. In the case of Super Blue, there are a few to consider. When applied too much strength in a single point, it can chip which is why it is often hammered in softer stainless steel to give it more support. Knives made from it are built for their cutting ability, not for a showcase of power, so ensure you are buying it for the right reasons.

As it’s a high carbon knife, it will discolour and take a patina through use as it oxidises. Bear in mind that it does not affect the performance of the knife but not everyone likes this. We see it as the knife taking on a unique character all of its own, creating history with its owner, so fair to say we like it. Again, this is why it is often laminated in stainless steel to protect the cutting edge.

There are other unseen compromises too, Super Blue steel is difficult to work with also for the blacksmith. This leads to more ruined or unusable blades which pushes up the cost of those blades that are finally finished. This contributes to the increased cost of these blades.

Summing up, it’s about as good as carbon steels get – it allows for an insanely sharp edge, but need some attention to ensure you keep getting the most out of that edge. For a more robust/forgiving carbon steel take a look at White Carbon Steel (Shirogami).