For centuries, Japanese artisans have passionately honed their skills, breathing life into blades that epitomize a harmonious blend of sharpness, strength, and beauty. The art of Japanese knife making is an inheritance from the Samurai, who demanded nothing short of perfection to match their unparalleled skills. Today, these revered techniques are passed down through generations, embodying the soul and craftsmanship of each individual maker.

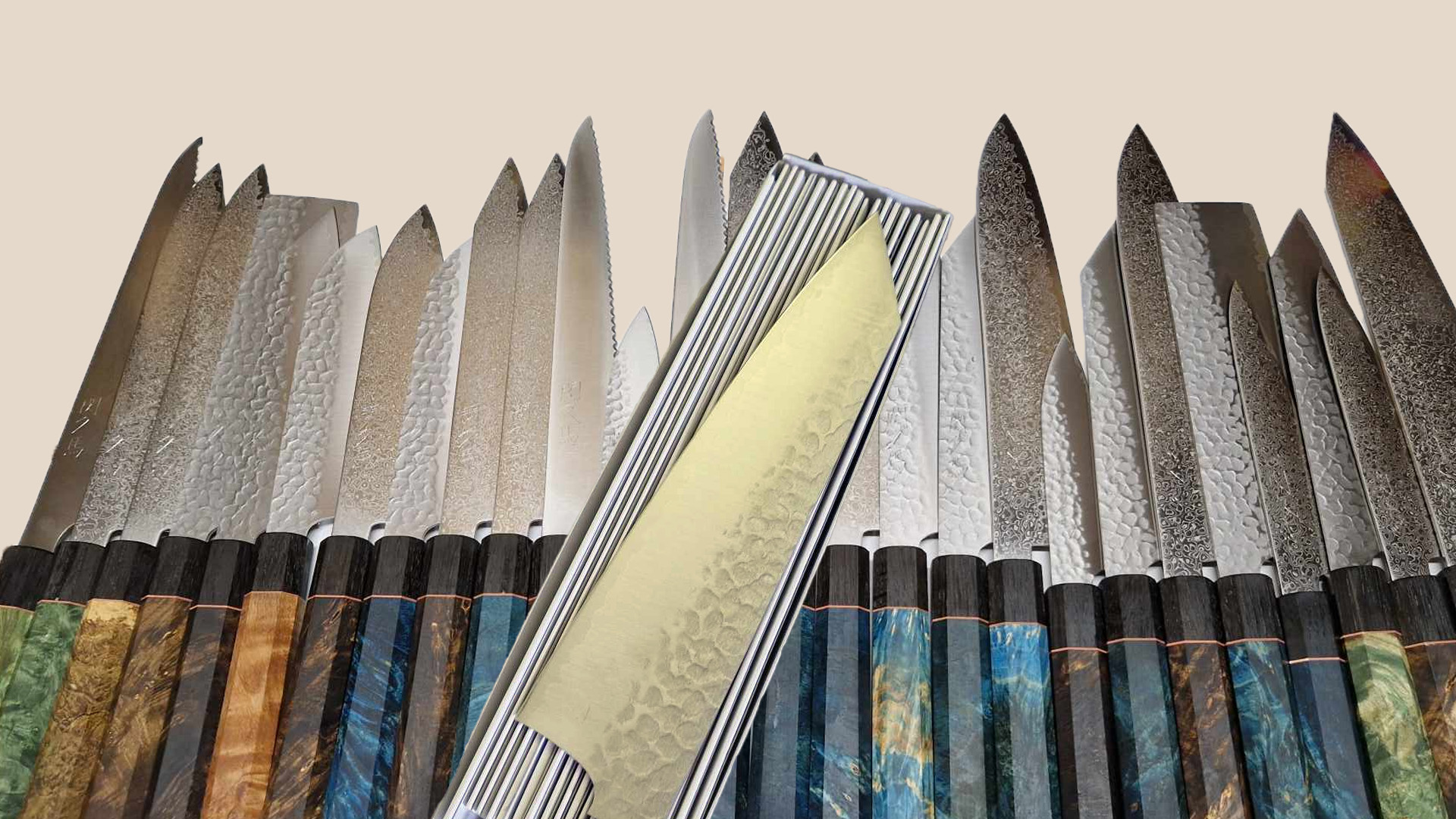

In the realm of culinary mastery, the Japanese excel in their unwavering dedication to perfection, impeccable craftsmanship, and an unwritten commitment to excellence. At Oishya, we proudly present our Sakai Kyuba Damascus high-carbon stainless steel knives, born out of the passion for knives, cooking, and all things Japan. Join us as we take you on a captivating journey, revealing the vibrant process behind the creation of these extraordinary blades. Discover why they are the ultimate choice for ambitious home cooks, particularly for women seeking to enhance their kitchenware and unlock a deeper joy in cooking.

Step 1. Joining the two sheets of different metal

The way the iron and steel are combined during creation is what makes for so many different Japanese knife types. Firstly, the iron is heated in a furnace that can reach 1000 °C, then the steel is placed atop the iron, the metals are reheated, and the blacksmith hammers them together. By combining soft irons with hard steel, the best qualities of both are brought together to form the foundation of a knife that is both hard to break yet keeps an edge.

Iron (softness): makes the knife flexible and less likely to break

Steel (hardness): gives the knife a sharper edge

The steel contains tamahagane, a type of ore made from iron sand and considered to be the very finest material. Though tamahagane is usually used as a material in Japanese swords, it is also employed to craft the highest class of Japanese knives. Our craftsmen also use it. Tamahagane made in a tatara (traditional Japanese furnace) is considered to be the most valuable and desired in the world. Also, the purest steel in the world is a type of Japanese steel called shirogami hagane (white paper steel).

Step 2. Setting the shape and strengthening the blade

Once the iron and steel have been fused, the skilled knife smith vigorously hammers the metal, shaping it into the desired form. Through this intense forging process, microscopic air bubbles within the metal are compressed, resulting in a blade that is not only formed but also significantly strengthened.

Step 3. Coarse sharpening

Using a whetstone, the knife smith proceeds to roughly sharpen the cutting edge of the blade, refining its initial shape. This coarse sharpening stage sets the foundation for the knife’s cutting performance.

Step 4. Quenching

To achieve the desired hardness, the knife undergoes a crucial step called quenching. The heated blade is swiftly immersed in oil, rapidly cooling it and maximizing its hardness. This rapid cooling process further enhances the blade’s durability and sharpness.

Step 5. Tempering

Following the quenching process, the craftsman meticulously immerses the knife in a low-temperature liquid, such as oil, for approximately an hour. This tempering phase, conducted at temperatures lower than those of quenching, restores the blade to its original state. Through tempering, the blade gains resilience, ensuring that the edge remains robust, resistant to chipping, and less prone to damage.

Step 6. Fine sharpening of Japanese knives

The final step in the knife-making process involves the meticulous fine sharpening of Japanese knives. This stage refines the blade’s cutting edge to achieve an exceptional level of sharpness and precision. Skilled craftsmen carefully hone the edge using various grits of whetstones, gradually refining it to perfection. This fine sharpening process ultimately determines the knife’s exceptional cutting performance, allowing it to effortlessly slice through ingredients with precision and ease.

Crafted with meticulous attention to detail, Japanese knives possess an extraordinary sharpness and exhibit magnificent designs. As a result, they effortlessly glide through delicate ingredients like raw fish for sashimi, preserving the food’s pristine shape without any compromise. We are immensely passionate about these knives, and we are certain that you will share our love for them too.

Embracing the Joy of Cooking:

Japanese knives, crafted with unparalleled mastery and captivating design, become an extension of the cook’s passion and commitment. As a home cook, you deserve the finest tools that not only elevate your culinary skills but also infuse joy into your cooking experience. Our Sakai Kyuba Damascus high-carbon stainless steel knives epitomize this pursuit of culinary excellence. Each knife is painstakingly crafted to empower your kitchen adventures, unbridling your creativity, and creating unforgettable moments with every meal.

Japanese knives embody the essence of artistry, tradition, and exceptional functionality. The Sakai Kyuba Damascus high-carbon stainless steel knives from Oishya are born out of the unwavering dedication of skilled artisans, transforming mere tools into works of unparalleled mastery. As a brave, self-fulfilled, and ambitious home cook, you deserve nothing less than the best to unlock your culinary potential and create extraordinary moments within your home’s heart. Elevate your cooking journey with our knives, and savor the vibrant art of Japanese craftsmanship with every slice,