When it comes to kitchen knives, the steel used in their construction is one of the most important factors determining their performance, durability, and longevity. Two of the most popular stainless steel varieties for premium Japanese kitchen knives are VG10 and AUS10 – but what sets them apart, and which one is right for your needs?

At Oishya, we pride ourselves on offering a range of handcrafted Japanese kitchen knives made from the finest materials by skilled artisans. Our Sakai Kyuba line features blades forged from robust AUS10 stainless steel, while the knives in our Seki Kyuba Core collection boast ultra-premium VG10 steel. We also have a top-of-the-line Seki Kyuba PRO series made with R2/SG2 powder steel for those seeking the ultimate in high-performance cutlery.

But before we dive into the specifics of VG10 vs AUS10, let’s first cover some basics on stainless steels and what qualities make them desirable for kitchen knife applications.

Stainless Steels 101

Stainless steels are iron-based alloy metals that contain a minimum of around 10.5% chromium. This chromium content gives the steel excellent corrosion and stain resistance by allowing a thin, passive layer of oxidised chromium to form on the surface, protecting the underlying metal.

Beyond chromium, stainless steels typically contain varying amounts of other metallic elements like carbon, nickel, molybdenum, vanadium, and manganese. These additional alloy components influence qualities like hardness, edge retention, wear resistance, and toughness.

For kitchen cutlery, the ideal stainless steel needs to strike a balance between hardness for acute edge sharpness and edge-holding ability, while still maintaining enough toughness and flexibility to withstand the impact and stresses of regular use without chipping or breaking.

So with that context out of the way, let’s compare and contrast VG10 and AUS10 to help you decide which premium Japanese stainless is right for your needs.

VG10 Stainless Steel

Developed in the 1970s, VG10 is widely regarded as one of the finest stainless blade steels available today. It has earned a sterling reputation among chefs, knife makers, and enthusiasts for its superb combination of razor-sharp edge capabilities and excellent corrosion resistance.

The “VG” designation stands for “V-Gold,” referring to the high vanadium content along with a smattering of other alloys in this complex steel. Here’s a breakdown of its key elemental composition:

– 1% Carbon

– 15% Chromium

– 1% Molybdenum

– 0.2% Vanadium

– 0.5% Manganese

That high carbon and vanadium content gives VG10 exceptional hardness and wear resistance properties. Knives made from VG10 can take a stunningly sharp edge in the 60-62 HRC range on the Rockwell hardness scale. This translates to lasers-like sharpness and superior edge retention compared to many other steel varieties.

At the same time, the hefty chromium content provides excellent stain and corrosion protection, making VG10 quite resistant to pitting, rust, and other forms of deterioration from moisture and acidic foods. Its toughness is also more than adequate for kitchen duties, giving it good impact and bending resistance to avoid excessive chipping or breaking from stresses.

However, VG10 can be tricky and expensive to produce properly. It requires very precise heat treatment and tempering processes to maximise its desirable characteristics while minimising brittleness and inconsistencies. This drives up costs, making VG10 one of the more premium options for high-end kitchen cutlery.

Our Seki Kyuba Core series proudly features blades made from fine-grained, consistently heat-treated VG10 produced by the master bladesmiths of Seki City in central Japan. These knives offer the ultimate in sharpness, edge longevity, corrosion resistance, and overall performance for the most discerning home chefs and culinary enthusiasts.

AUS10 Stainless Steel

While not quite as exalted as VG10 among aficionados, AUS10 is still an excellent stainless knife steel that offers a fantastic balance of desirable qualities at a more affordable price point. It was developed in the 1990s by Aichi Steel in Japan as an upgrade over AUS8 with improved hardness and edge-holding ability.

The AUS (or “Aichi Ultra-Strength”) designation refers to this higher hardness and wear resistance compared to conventional Japanese stainless cutlery steels. Here’s a quick look at its principal alloy makeup:

– 0.95-1.1% Carbon

– 13.5-14.5% Chromium

– 0.1-0.5% Molybdenum

– 0.1-0.3% Vanadium

With that elevated carbon, chromium, and vanadium content, AUS10 can achieve hardness levels between 58-62HRC. This allows it to take an extremely sharp and durable edge that vastly outperforms budget stainless steels, while nearing (but not quite matching) the impressive edge retention of super-premium steels like VG10.

AUS10 has very good corrosion and stain resistance thanks to its high chromium and balanced alloy mixture. And thanks to more accessible and cost-effective production methods, AUS10 knives can deliver premium performance at a much more affordable price tag compared to VG10.

For those seeking a big step up in blade sharpness, edge longevity, and low-maintenance robustness from standard stainless kitchen knives without the ultra-premium price point, AUS10 hits an outstanding sweet spot. It’s the steel of choice for our Sakai Kyuba line, which pairs impeccably heat-treated AUS10 blades with elegant traditional Japanese handles and construction.

VG10 vs AUS10: Performance Comparison

Now that we’ve covered the key properties, compositions, and advantages of each steel, how do VG10 and AUS10 actually stack up in real-world kitchen performance? Let’s run through some of the major considerations:

Edge Sharpness & Retention

Both of these steels can achieve impressively acute edges, but the higher carbon and vanadium content gives VG10 a slight advantage here. VG10 edges can be honed to slightly keener levels with better overall edge holding and reduced microchipping compared to AUS10. AUS10 still yields supremely sharp edges that far outlast common stainless varieties, just not quite as extreme as top-shelf VG10.

Corrosion & Rust Resistance

Both VG10 and AUS10 boast excellent corrosion resistance thanks to their high chromium content, but VG10 takes the crown in this category too. The increased chromium and balanced metallurgy of VG10 makes it slightly more impervious to staining, pitting, and rusting from acids and moisture. But proper care and avoiding prolonged exposure will keep AUS10 corrosion at bay too.

Toughness & Impact Resistance

While harder steels are more prone to chipping and brittleness, both VG10 and AUS10 offer very robust toughness for kitchen workloads compared to ultra-hard blade steels. VG10 may exhibit a touch more microchipping at the apex over time, but AUS10 is the slightly tougher of the two with greater impact and bending resistance.

Ease of Sharpening

The complex, finely grained, hyper-hardened metallurgy of VG10 makes it a bit trickier to sharpen than AUS10 for casual maintenance. AUS10 can be touched up relatively easily, while VG10 requires more attentive and skilled sharpening to avoid damaging the ultra-fine edge geometry. Both will require professional sharpening services eventually though.

While VG10 demonstrates a slight objective performance advantage in most areas, for many home cooks the difference may seem negligible compared to the higher costs. But for those who demand the absolute pinnacle of premium kitchen cutlery, VG10’s minor advantages may justify the splurge. Whichever you choose, you’re getting an elite, low-maintenance steel that vastly outperforms budget knives.

Caring For Your VG10 and AUS10 Knives

To get many years of fantastic performance from your premium Oishya VG10 or AUS10 knives, proper care and maintenance is essential. Always hand-wash and thoroughly dry the blades after use to prevent moisture buildup and potential corrosion. Use a soft sponge or cloth and avoid abrasive pads that can scratch the super-fine edge geometry.

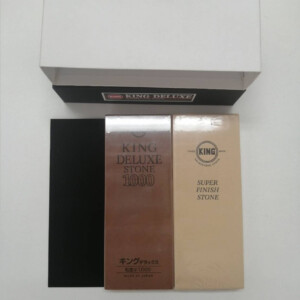

Honing the blades regularly with a smooth ceramic rod will help maintain the razor-sharp edges between more thorough sharpenings. When it’s time for sharpening, you may want to consider using a professional service to ensure the ideal bevel angles and edge finishes are achieved.

Storing the knives properly is also important. Wall-mounted magnetic racks or individual blade guards are ideal for preventing accidental chips and protecting the edges. And of course, always use proper cutting surfaces like wood, hi-soft synthetic, or rigid rubber boards to avoid excessive blade abrasion and impact.

With conscientious care, your Oishya VG10 and AUS10 knives will provide years of unparalleled cutting performance in the kitchen. And if you ever have any questions, our team is always happy to provide guidance.

The Cutting Edge of Craftsmanship

Ultimately, whether you opt for the ultra-premium VG10 steel of our Seki Kyuba Core series, the exceptional value of AUS10 in the Sakai Kyuba lineup, or even step up to the ultra-high-performance R2/SG2 powder metallurgy of our Seki Kyuba PRO knives, you’re getting cutlery crafted with uncompromising attention to detail.

Every Oishya knife is a handmade work of functional art produced by skilled artisans in the knife-making capitals of Japan. From the meticulous forging and heat treatment of the high-alloy blade steels, to the traditional Japanese handle construction and elegant finishing details, no aspect is overlooked. We’re passionate about not just equipping home kitchens with premium cooking tools, but also educating and empowering our customers to make educated decisions about their culinary gear. Because at the end of the day, the right knife is an indispensable extension of the chef wielding it.

So whether you’re an avid gastronome always seeking to elevate your kitchen game, or a budding culinary enthusiast looking to invest in top-quality tools, we’re here to help. Our informative articles, video guides, and friendly team of experts aim to demystify the world of elite Japanese blades. We’ll ensure you find the perfect knives for your needs and budget, along with the know-how to care for and maximise their incredible performance for decades to come.