We’ve covered essentials on cutting boards in our last article, but as with everything in life, you can always keep digging and learning more and more specifics which can help you to find the perfect product. Same with such a simple product – one could think – as a chopping board.

Some people value good price over quality and that’s perfectly fine. It’s enough if the product does its job for at least some time. Some prefer to spend more time learning about the product they intend to get, hoping to choose the best quality one. Once you recognise that there are apples and there are oranges and that they are not necessarily interchangeable, you start understanding that buying a cheap product doesn’t come out so cheap in the long term anymore. The price can’t necessarily tell you which is better crafted or more durable either. Then there is the design factor.

Do you want durability or do you care about aesthetics more? Or both? Are you concerned with how the trees are harvested or not? How much do you care about your knives? Hygiene? How much space do you have? Will you leave it out all the time or does it need to be able to store easily? Will it keep it’s good looks or is it something you want to hide? Do you want to support your local woodworker?

The choice of materials

Generally, you can make a board of many materials, but the following ones are the most common:

- End grain wood

- Edge or face grain wood

- Plastics (made with petroleum products)

- Rubber

- Bamboo and composite boards

There are now many studies that compare the healthiness of plastic vs. wood (spoiler alert – wood wins).

Understanding how wooden boards are made

End-grain blocks

- are made of ‘blocks’ with the grain in various directions (resists warping)

- are always a little thicker

- resist warping

- more expensive to produce

- are the ideal surface for cutting and chopping

- will not gouge (the fibres pull together after cutting)

- easy on knives (no resistance to the edge)

- hold knives in place (won’t slip as they go into the wood)

- recommended conditioning, regular seasoning

Edge-grain boards

- can be very thin as they are made up of strips or ‘board’ length

- can be one species or combinations of different woods

- are the ideal surface for presentation

- will gouge when cut on with a knife (like a lumberjack)

- harder on knives (but much better than non-wood)

- easier to construct (cheaper if used commonly found materials)

- they split if multiple species are used

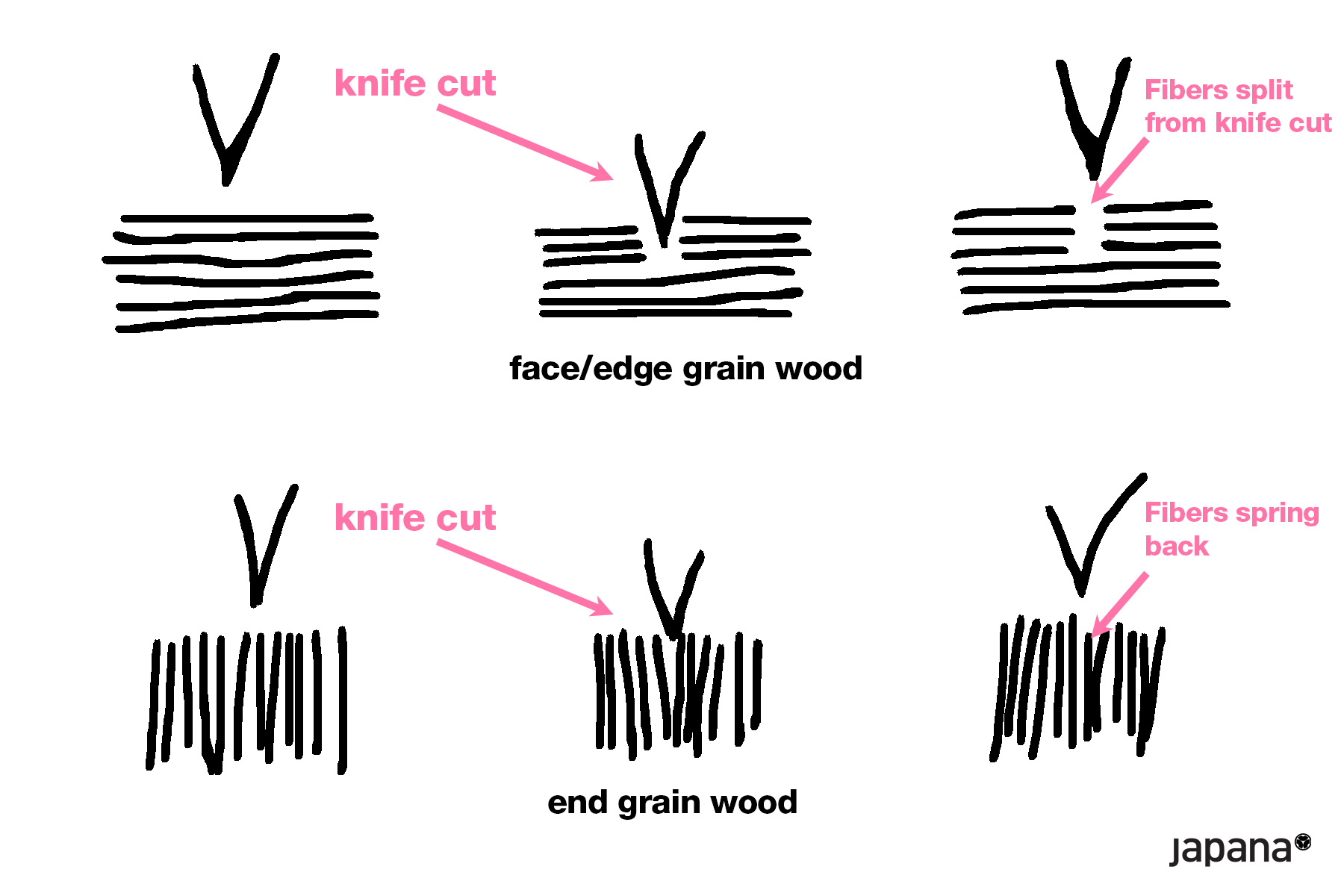

What happens to the grain/fibres of the wood?

Top row – in edge grain you can see how the fibres are broken/cut – this is work for your knife and why edge grain boards will gouge.

Bottom row – the fibres open up with a sharp knife. This shows how end-grain is easy on your knife and ‘self-heals’.

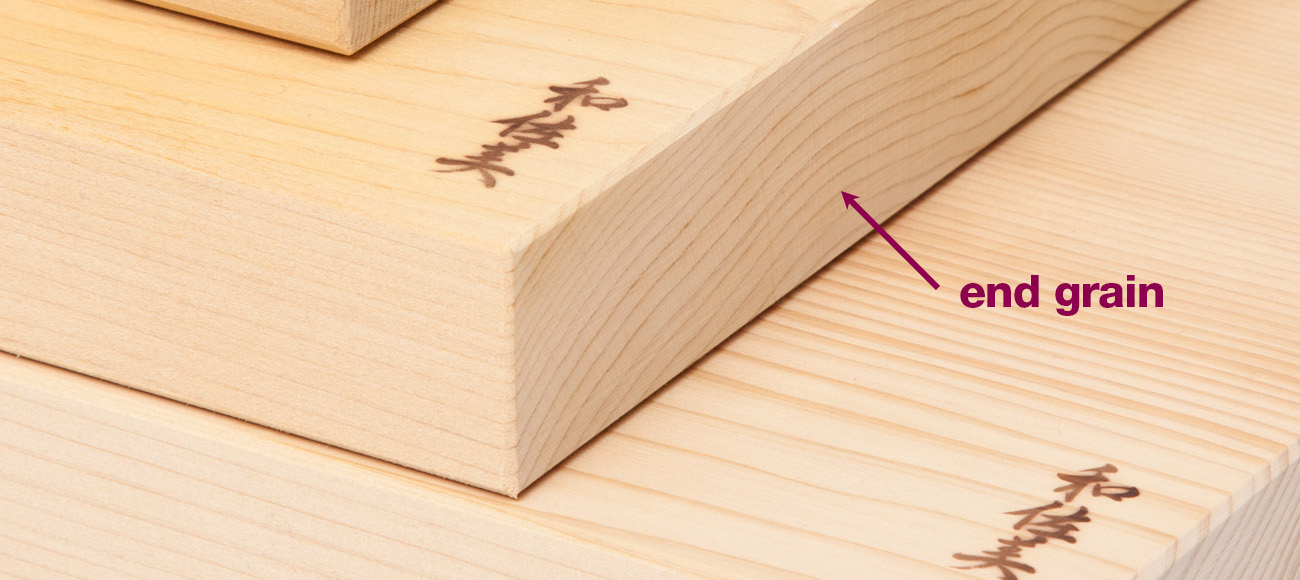

Above you can see on the edge on the right the end of the grain and the curvature of the rings of the tree and on the left the narrower, straighter grain lines of edge grain.

Feet or no feet?

Sometimes board has soft rubber feet attached, making a little gap so that you can lift it easily and so it doesn’t slip on your counter. It helps to ensure that moisture isn’t trapped underneath the board. However, many respected craftsmen won’t like to destroy the beauty of the natural wood with rubber. They argue that if you care for the board at least in the minimum way, like cleaning and drying the board after use – it will last you ages.

What are the best alternatives to end grain boards?

We wouldn’t be ourselves if we didn’t mention Aomori Hiba wood. The boards made of this tree are a single piece of wood, therefore end grain is irrelevant. Apart from looking great and its anti-bacterial properties, it’ll caress your blade as it touches it and smells beautiful when you wash it. Also because of the fact that it’s one piece, it tolerates wet much more than anything else. The downside is that it’s expensive as it’s a very precious and noble tree in Japan.

So, how big a board is big enough?

A rule of thumb is that when the knife is laid diagonally across the cutting board, there should be an inch or two of cutting board on either end of the knife. For example, a 10-inch (240mm) chef’s knife needs a cutting board that is at least 14 inches diagonally.