Product Description

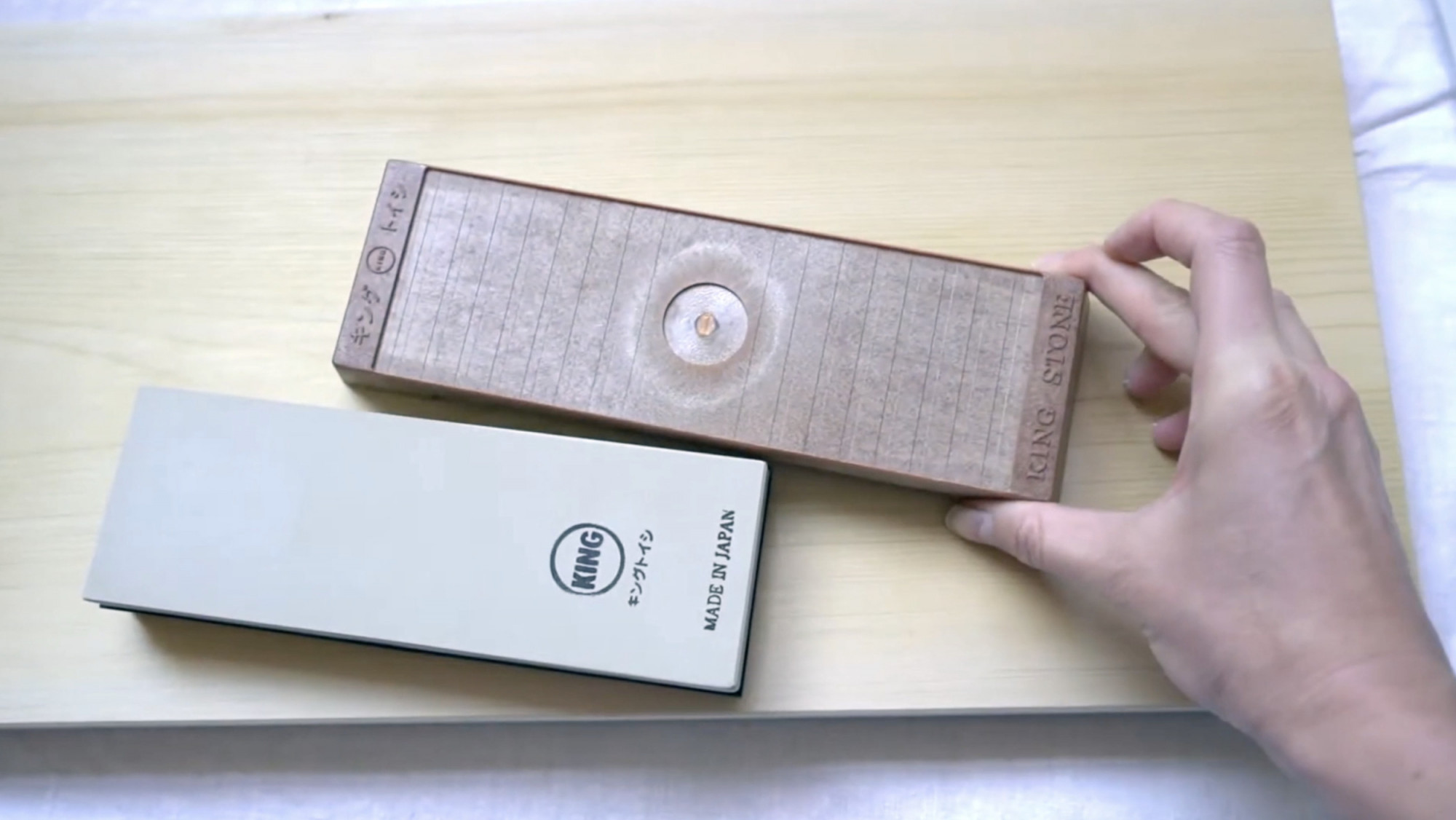

The King KW-65 1000/6000

This #1000/#6000 grit combination waterstone (whetstone) will restore a dull edge to a sharp one using the 1000 grit side. Put a mirror polish on the back and bevel of the blade using the 6000 side. Ideal for working blades that are dull and are not damaged. The two different grit sizes in one double sided stone make combination waterstones an excellent, cost effective way of owning a range of grits. Made from abrasive particles suspended in a bonding compound. The stone covers two consecutive stages in the sharpening process. Dimensions of the whetstone are 207 x 66 x 36mm.

King stones have earned a worldwide reputation. This is one of the most respectable sharpening stone manufacturer based in Matsunaga, Osaka in Japan. This sharpening stone features an average grit sharpening surface on one side, and a fine grit finishing surface on the flip side. This is the perfect stone combo for new or occasional freehand sharpeners.

Japanese Whetstones

Unlike other synthetic sharpening stones which consist of a single abrading agent, these Japanese water stones consist of aluminium oxide, carbide and nitride particles fused together. This blend is then mixed with a clay like bonder and baked at high temperatures to form the sharpening stone. The resultant stone is soft but sharpens very quickly. The soft bonding clay allows the abrasive particles to release very easily when the stone is soaked in water. This gives the user a constant supply of fresh cutting surfaces with which to grind, sharpen and hone their tools.

Now favoured by many professionals and sporadic users over the natural stones, when you purchase a synthetic Japanese sharpening stone you are guaranteed a stone with a uniform grit size that will produce consistent, high quality results when sharpening and will not vary in quality from stone to stone.